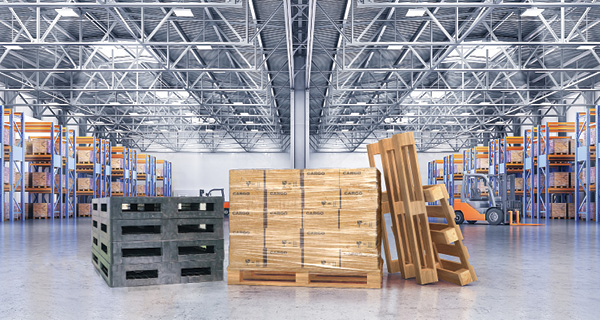

Pallets are an essential part of the pallet manufacturing, packing, transportation and retail industry. There is no shortage of pallet suppliers in the United States, but the wide range of options can also be misleading and overwhelming, unless you know exactly what to look for. To get an idea of what to expect and how to find a reliable pallet company, this brief discussion should prove to be helpful.

Get to Know Pallets Well

To make the right selection, it is important for us to be aware of the options available first. Therefore, the very first step should be that of getting to know pallets well enough. Which materials are used to manufacture pallets? Which of those materials are better suited for carrying your products? Are there customization options, or do pallets come in a prefixed size only? Let’s get the basics out of the way first by answering these questions in the most informative way possible.

Pallets Usually Come in 3 Different Sizes

The standard US industrial pallet comes in three sizes.

- 42” x 42”

- 48” x 40”

- 48” x 48”

However, these three are not the only options, since you can work with manufacturers to help them create a more customized pallet with adequate dimensions for your business. We will discuss this in more details later on.

A List of Common Materials Used to Manufacture Pallets

Pallets can be made out of a variety of materials, and the material is chosen based on:

- What they are meant to carry on them and how

- The customer’s requirements and budget

- The size of the pallets, if customized

From different types of wood to composite, plastic and metals, there is no shortage of choice here. Let’s take a look through the most commonly used pallet materials next.

- Wood: By far the most commonly used pallet material in industrial shipments

- Plastic: Although it covers only a very small fraction of the industry’s needs, plastic comes in second as a material choice for industrial pallets

- Composite: They come in a variety of designs, but composite in general is a very sturdy pallet material, albeit quite expensive

- Wood & co-polymer polypropylene pallets – Co-polymer polypropylene is a type of plastic which is used to reduce weight and strengthen wood pallets

- Aluminum (cheaper) and stainless steel (stronger) – The two most common metals used for pallet manufacturing are aluminum and stainless steel

- Paper – When it comes to cardboard, hardboard and other paper made pallets, they cater to very specific, low-durability needs

Now that the basics have been overviewed, let’s go over the most important aspects of a good pallet supplier next.

Reputation in the Industry

If the pallet provider is any good, they will have a good business reputation to bank on. Talking with others in the same sector could help in finding out more about each option. The core B2B sector is not one where suppliers can escape a good or bad reputation, so use that to your advantage.

Performance and Cost-Effectiveness

Considering that pallets are responsible for keeping merchandise secured during storage, loading and transition, their quality must be up to the standard necessary. There is also cost efficiency to consider of course, which further complicates the selection process.

However, while other pallet manufacturers struggle to provide quality and performance in a cost-effective package, GreenBlock-powered pallets from Pallets LLC provide better performance at a cheaper price! These are sustainable, super lightweight (80% lighter than the standard) products which use only a fraction of the wood usually needed to construct a standard GMA wood pallet. Each pallet is also cheaper and stronger (pound-per-pound) than the GMA pallets, making them a superior choice in every possible aspect.

Customization Options

On top of offering ready-to-ship pallets in the three standard sizes, the manufacturer should provide their customers with additional sizing options, if they have the need for it. If you can save more space and money by customizing the size of your pallets, there’s no reason why you shouldn’t.

Aside from size, there are also several other design aspects of a pallet that can make them a lot better suited for their intended purpose. If the manufacturer is given exact information regarding the following aspects, they should be able to make each pallet more effective for their customers.

- Products which the pallets will be holding

- If and how the pallets are to be entered into the production machine

- Shipping information and technique

- Maximum weight that each pallet will be expected to carry on them

Discuss these aspects with the pallet company and they should be able to tell you whether the cargo can benefit more from solid deck pallets, double face pallets, double wind pallets, stringer pallets or standard decks.

Those with an active business may find that their pallets are underperforming or becoming a cause for concern, in case they partnered up with the wrong manufacturer. If that happens, the owner needs to switch providers as soon as possible. When a company is fairly new to a segment though, they can avoid the entire learning curve with these pointers in mind.