Ball valves are a widely popular device for various industry applications. Their simple yet reliable design makes them a sought after choice for residential use cases. While their affordable manufacturing process and straightforward maintenance add to their importance for commercial settings.

But before you move forward with installing these valves into your structure, you may be interested to learn exactly how they work. To help you gather this information, here’s a breakdown of the function and basic structure of these valves.

They Stay True to Their Name

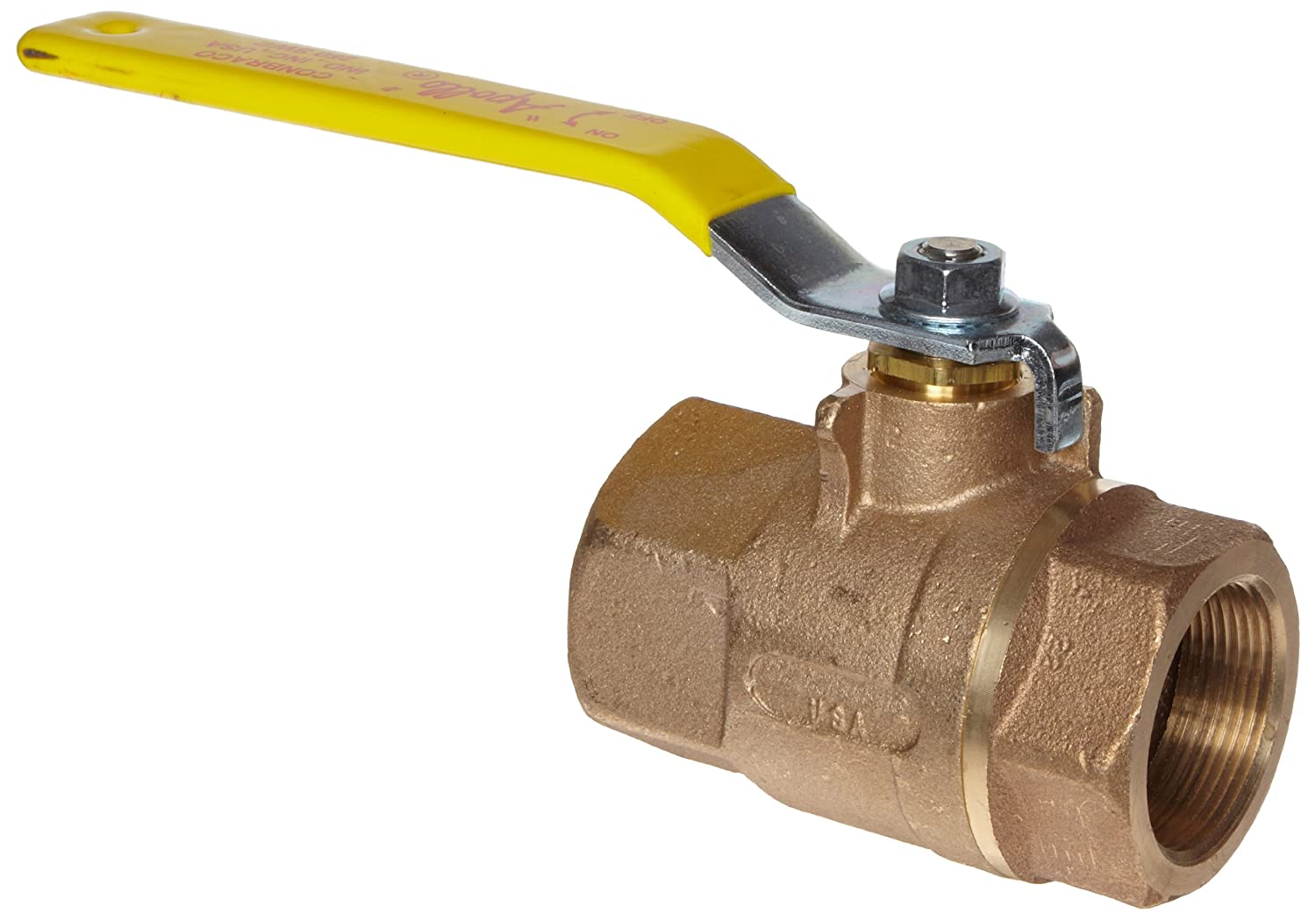

The ball valves get their name due to the mechanism they use to control flow through connected structures. At its core, the ball valve has a spherical closure that can rotate under its body. To allow flow through the pipeline, this ball has a bore or port within it.

When the valve is off, this port turns at a 90 degree angle to both sides of the valve’s body. This way, its closed-ends face the pipeline or the source of the flow and stop gas or liquid from passing through.

When the valve is on, this port faces the source of the flow directly and allows it to pass through the pipeline. This lets the liquid or gas to flow through the ball’s port uninterrupted.

The Ball Valve is Controlled by a Stem and Handle at the Top

Ball valves are one of three quarter-turn valves. They share this distinction with butterfly and plug valves. As the categorization suggests, the design of these valves allows them to open and close with a simple quarter-turn.

Instead of being controlled by a wheel, a ball valve typically opens and closes through a handle. This handle is attached to a stem at the top of the valve and just needs a quick turn to manipulate the direction of the spherical closure under the valve’s body. This also makes it a fast-turning or shutoff valve that requires minimal intervention to open and close.

Different Variations Are Also Available

Apart from the traditional ball valve design, the valve is also available in a few variations. Learning about them helps you choose the best fit for your specific use.

Reduced-port or Reduced-bore Valves

A ball valve can have a reduced-bore size, which limits the flow of the liquid or gas despite the size of the attached pipeline or structure.

V-port Valves

V-port valves have a V-shaped bore. This is typically used in situations where you need more control over a specific process.

Three-way and Four-way Valves

A ball valve is also available with a three-way or four-way port. These variations are able to fulfill the needs of more complex structures.

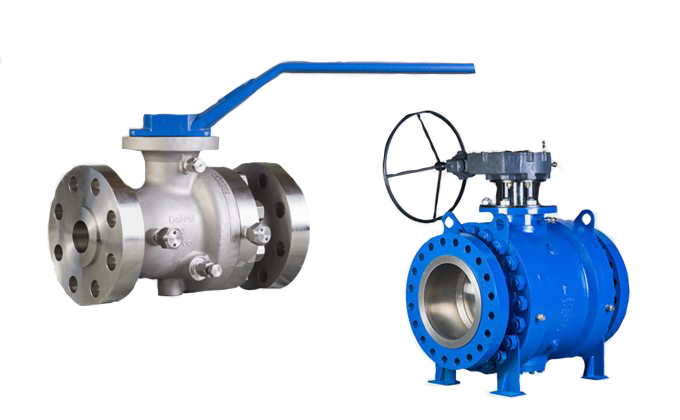

Trunnion-mounted Valves

For high pressure applications, you can turn to trunnion-mounted ball valves. These valves use anchoring at the top and bottom to provide more support to the spherical closure.

Floating Valves

A floating ball valve is attached to the stem only. When the handle is moved, the spherical closure floats with it. But when it is released, it presses against the body or seat.

Rising Stem Valves

Along with being attached to the stem, these valves also rise when they are opened. This not only causes them to release flow through the bore but also lets it pass through the surface of their core. This prevents friction against the seat and minimizes long-term issues that arise out of such scenarios.

By choosing the right ball valve, you can ensure to get the most out of its application. In case you need further information about finding the ideal valve for your structure, don’t hesitate to reach out to an expert.