These days, the world of technology is developing at an accelerating pace. New technologies appear on a regular basis, but the old ones are revamped as well.

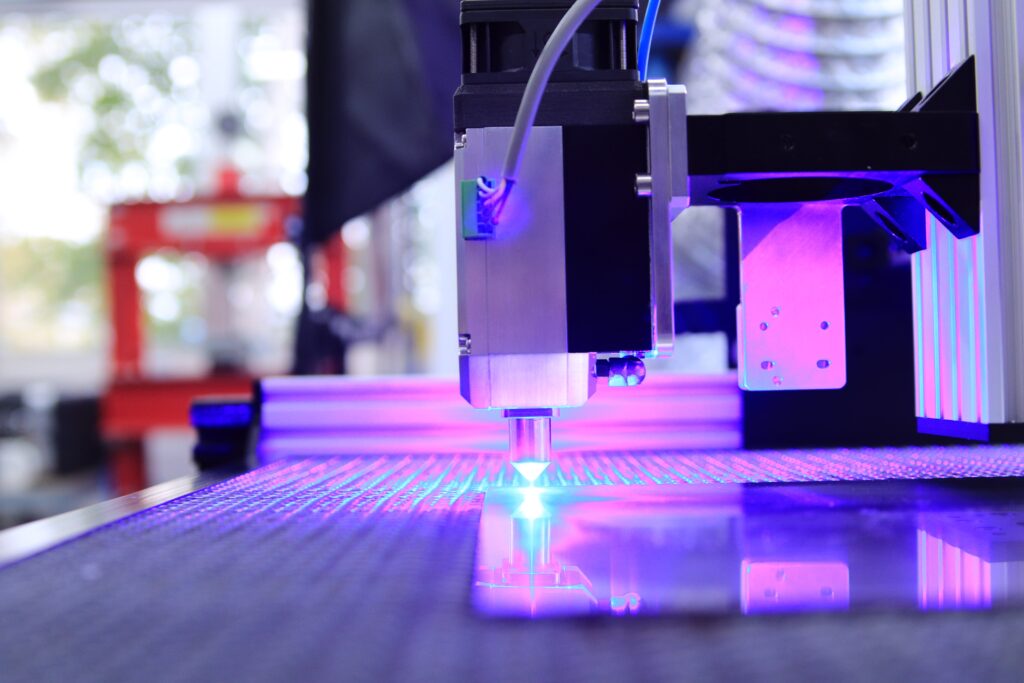

3D laser scanning is one of the cutting-edge technologies that has recently revolutionized the way we capture, analyze, and make use of spatial information.

It offers a powerful and precise method for capturing the physical world in three dimensions.

Let’s then explore what 3D laser scanning is, how it works, and which industries can benefit from implementing this technology.

What is 3D laser scanning?

In brief, 3D laser scanning is a non-contact, high-precision technology using laser beams to measure and capture the exact shape and dimensions of:

- objects,

- structures, or

- environments

in three dimensions.

A laser scanner emits laser pulses towards a target, and the reflected pulses are measured to create a detailed 3D point cloud.

How does 3D laser scanning work?

- Emitting rapid laser pulses towards the target area by a laser scanner.

- Reflecting back the laser pulses to the scanner once they hit an object or surface.

- Measuring the time it takes each pulse to return to the scanner and calculating the distance to the object’s surface.

- Forming a dense 3D cloud by using distance measurements and recording numerous points on the target’s surface.

- Processing the collected data.

- Creating a detailed point cloud of the scanned area or object.

What are the benefits of 3D laser scanning?

Apart from the straightforward and ordered process, 3D laser scanning has other advantages that make it a cutting-edge technology. These are:

- highly accurate and precise measurements, reducing human error,

- efficiency thanks to quick data collection and analysis,

- safety for operators,

- cost savings by reducing the need for physical re-measurements and site visit,

- comprehensive data, allowing for in-depth analysis and visualization.

Where can 3D laser scanning be applied?

Truth be told, 3D laser scanning can be applied across various industries. It is impossible, then, to outnumber all the use cases, but let’s go through a few.

In architecture and construction, it can help to create accurate as-built models for construction projects and to document and preserve historical structures and monuments.

Moreover, in the engineering landscape, laser scanning can assist in the design and maintenance of complex industrial facilities, such as offshore platforms, vessels, refineries and factories.

In manufacturing, this cutting-edge technology can be employed to inspect manufactured parts for defects or deviations from design specifications.

Finally, in the geospatial industry, 3D laser scanning can help to map geological features and assess terrain conditions.

Summing up, 3D laser scanning is a highly versatile technology with a wide array of applications across industries. Nevertheless, as technology advances, 3D laser scanning can become even more beneficial to various fields, contributing to greater efficiency, safety, and innovation.