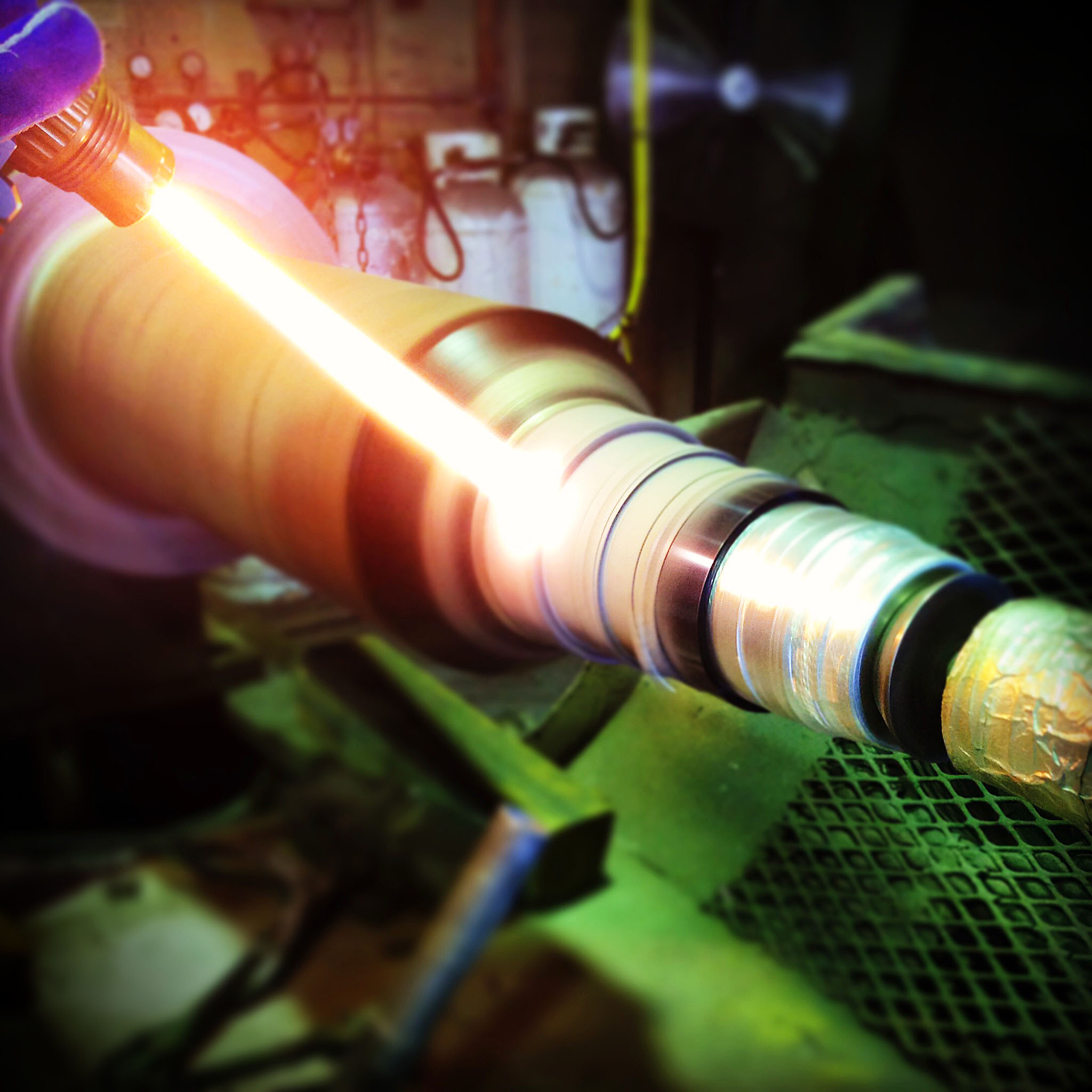

HVOF or High-Velocity Oxygen Fuel Thermal Spraying is a process of coating a material or ‘substrate’ with a high velocity yet low-temperature technique. The coating particles spray at ‘supersonic’ speeds allowing what boasts an ‘extreme kinetic energy,’ creating a bond to the substrate resulting in a heavy, dense coat.

There note to be many varieties of HVOF spray guns and different processes offering unique fuel offerings such as natural gas, hydrogen, or kerosene as well as oxygen source of either compressed air or pure oxygen. The procedure is suitable in creating an HVOF coating for several materials such as:

- Titanium

- Monel

- Hastelloy

- Tungsten

- Alloys of iron base

- Ranges of super alloy

- Chrome/nickel carbides

- Inconel

Advantages Of HVOF Technology

The intense heat and spray capacity of HVOF in combination results in a surface of extraordinary hardness with exceptional adhesion to the material and incredible resistance to corrosion. The claim is that the bond created with the substrate equates to more than 12,000 psi strengths allowing almost perfect resistance capacity for wear and corrosion in environments consisting of high temperatures. Some pros and cons of this thermal spraying system:

PRO: Coatings are harder.

Carbide phases see less degradation resulting in considerable hardness.

PRO: Greater wear.

Resistance to wear is improved due to the fact that the surface is much more durable, and bond strength is more exceptional.

PRO: Results are smooth and dense.

The impact velocity is exceptionally high, with resultant denseness and a smooth appearance.

PRO: Thick overall quality.

Because the process involves less residual stresses, it allows for extraordinary thickness.

PRO: Bonding is exceptional.

The bonding strength supersedes what would be anticipated allowing function in extreme atmospheres.

PRO: Resistance to corrosion is enhanced.

Corrosion protection is increased because the coating is less porous, adding to the lifespan of the finished product.

Thermal spray coatings, which are achieved through a variety of different processes, offer lesser quality than that of HVOF. These techniques provide several unique properties for a broad range of applications for many industries, becoming one of the most popularly used methods for making dense surfaces over several types of materials. For guidelines on the procedure go to https://www.corrosionpedia.com/definition/632/high-velocity-oxy-fuel-spraying-hvof .

As with all processes in the world, there are both pros and some cons to take into consideration. Downsides don’t necessarily indicate a reason not to use the system; it just provides a heads up to a few of the challenges.

CONS: Elevated Expense.

This spraying process comes in at a higher price point when compared to flame spray or electric arc spray because the equipment necessary for functioning is more costly.

CONS: Manual functioning is not ideal.

Automated manipulation is needed for the spray gun in this spraying process. Manual is not really an option in this method.

CONS: Specialized services for operation:

In order to achieve ideal results, it’s important to have employees who are dedicated to operating the specific equipment for these functions. It may result in extra costs like training, salaries, etc. but the investment is worth the advantages.

CONS: Application has restrictions;

There are limits as to where HVOF is not to be used, such as in instances of surface engineering for internal surfaces such as the inner area comprising a cylinder-type substrate.

CONS: Size restrictions for powder: There is a need to use size distributions of a narrower quality.

Some cons may pose a problem for specific applications or perhaps in certain industries, particularly if there is a need for cylindrical coating in any given situation. The HVOF would not be suitable for this type of application.

The best first step in finding the option that would work best for your needs is to reach out to experts in the field who can knowledgeably answer questions relating to your specific situation. Click for reasons HVOF may benefit your industry.

There is also a multitude of information found on the web that can further explain the ins and outs of HVOF along with tutorials to see how it actually works as a means to help educate you so you can make a more informed decision. If you’re involved in an industry that can benefit from this methodology, claims suggest it will serve you well.