Wood turning is a favorable subsection of woodworking, so much that some wood turners don’t really care about the other aspects relating woodworking, except turning. To learn the skill of wood turning, all you require are skew chisels, some sharp gouges, parting tools and a good lathe. You must find a way to keep your tools sharp for them to cut properly. It is worth learning a bit more about wood turning safety which can go a long way in assisting you with becoming a professional wood turner. However, you must have a good lathe. And if you are more into metalworks, then Summit has an awesome selection of metal lathes that can help you with your projects.

Start with a base

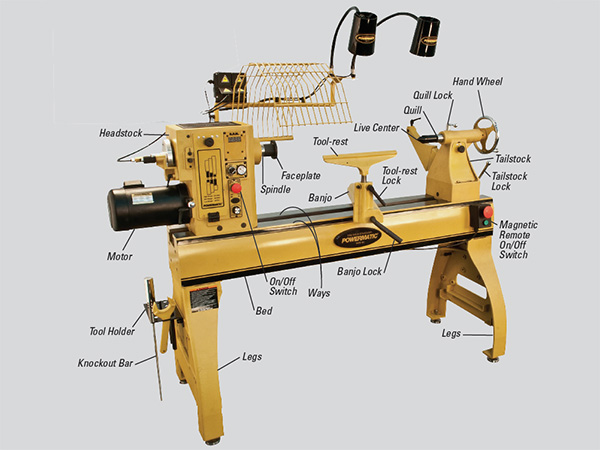

A good woodworking lathe must contain a good basis, and this starts with the bed. Whether you opt for a mini-lathe or a full-size lathe for turning pens and various other small items, or a midi-lathe that falls in between, the lathe must feature a solid bed. This part is the primary horizontal beam that runs across the footing of the lathe. The beam is usually made from cast iron since it must be heavy to keep a lathe from vibrating once the wood starts spinning on the motor. Even the faintest vibration can make turning tricky and become unsafe. The sturdier and more solid the base is, the easier it will be to use the lathe. Another consideration is the length of the bed. If you’re looking to turn table legs, you will require a longer bed than the case would be for pens and bottle stoppers. With certain midi-lathes the bed can be extended. While it can be a versatile option, if you’re going to turn many spindles of about 36-inches in length, a full-sized lathe with an unremitting solid bed would be the better choice. When the base is considered, the lathe height can be a worry. When it comes to lathes for woodworking, the spindle must be at the same height than your elbows if you’re standing in the lathe. When a spindle is too low, you will have a sore back from all the bending, and when it is too high, you’ll find it problematic to keep your tools in appropriate alignment with the lathe’s tool rest.

Here is an interesting article we found from Lathe Matters where Mr Charles Wilson showed how he surveyed 400 hundred woodturners- https://www.lathematters.com/best-wood-lathe/

Motor and headstock

Lathe motors varies from 1/8 to 3 horsepower with various speed controls, usually between 500 to 4000 RPM. The larger your motor, the larger the tool you can turn, since the motor is responsible for the workpiece turning at a stable speed. It you’re planning on turning spindles and bowls, you will require a drive center and faceplate which will interchange to keep the workpiece in place without a tailstock. If you’re intending on turning big bowls, the headstock must rotate away from the base to leave room for a large bowl and using the tool rest.

Tailstock

The tailstock is basically the rotating pin in the opposing end of the headstock. This piece keeps the spindle fixed and rotating consistently. A tailstock must lock securely in a position along the bed, permitting maximum versatility in the various turning types you’re considering.

Tool rest

This is probably the most essential piece of the lathe. The tool must always rest against the tool rest. Free handling is not safe for any cut on the lathe. One should be able to adjust the tool rest to whichever position is needed to lead the tool to the timber. Similarly, a tool rest should be locked securely into the desirable position. A loose tool is just as unsafe than no tool rest.

Power switch

The size of the power switch is often overlooked when a lathe is used. Various table saw manufactures included large paddle switches on the table saws before to permit the user to turn off the tool with their leg when they’re busy holding the tool with their hands. While this may seem like overkill on the lathe, sine the turner supports the cutting tool but not a workpiece, it still is essential to have an on/off switch which is easily accessible to turn off promptly when needed.