Evolution Of SCM:

While the previous supply chains were focused on the accessibility, development, and cost of actual resources, the present inventory chains are about the administration of information, administrations, and items packaged into arrangements. Current store network the executive’s frameworks are about considerably more than exactly where and when. Inventory network the board influences item and administration quality, conveyance, costs, client experience, and at last, productivity.

As of late as 2017, an ordinary store network got multiple times a bigger number of information than only five years sooner. In any case, under a fourth of this information is being examined. That implies the worth of basic, time-touchy information — like data about climate, abrupt work deficiencies, political turmoil, and microbursts sought after — can be lost.

Present-day supply chains exploit monstrous measures of information created by the chain cycle and are organized by logical specialists and information researchers. Future store network pioneers and the Enterprise Resource Planning (ERP) frameworks they oversee will probably zero in on streamlining the helpfulness of this information — breaking down it progressively with negligible idleness.

What is Supply Chain Management?

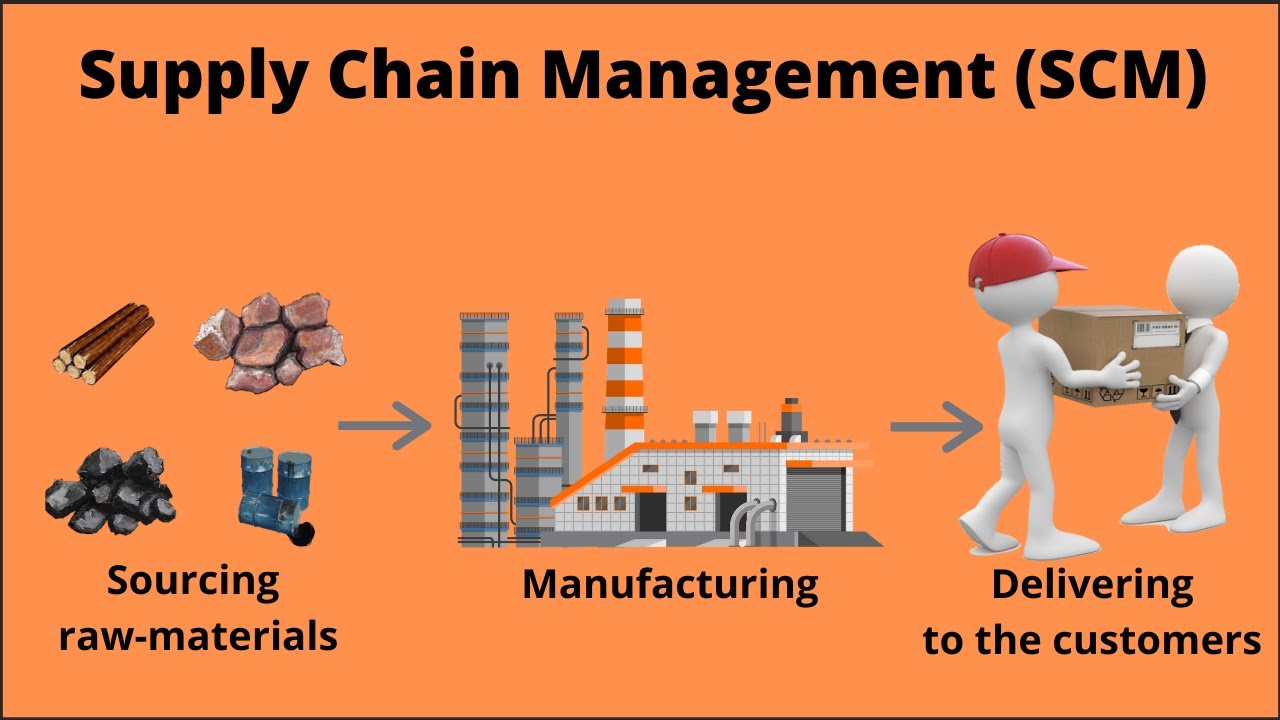

Supply chain management is the treatment of the whole presentation stream of a decent or administration — beginning from the crude parts the entire way to conveying the end result to the buyer.

Supply chain management (SCM) is the dynamic administration of production network exercises to expand client esteem and accomplish a supportable upper hand. It addresses a cognizant exertion by the store network firms to create and run supply chains in the best and most proficient ways imaginable. Store network exercises cover everything from item improvement, obtaining, creation, and strategies, as the need might have arisen to facilitate these exercises. Supply chain consulting companies can help with this kind of requirement.

Supply Chain Management (SCM) relies upon two focus contemplations:

- The first is that basically, every item that arrives at an end client addresses the aggregate exertion of numerous associations. These associations are alluded to altogether as the production network.

- The subsequent thought is that while supply chains have existed for quite a while, most associations stand out to what was going on inside their “four walls.” Few organizations got it, considerably less made due, the whole chain of exercises that eventually conveyed items to the last client. The outcome was incoherent and frequently incapable of inventory chains.

The associations that make up the production network are “connected” together through physical flows and information flows. You can get the supply chain organization well maintained with the help of e-procurement systems.

Physical Flows

Physical Flows incorporate the change, advancement, and limit of products and materials. They are the most noticeable piece of the store network. However, similarly as significant are data streams.

Information Flows

Information Flows permit the different inventory network accomplices to organize their drawn-out plans, and to control the everyday progression of merchandise and materials all over the store network.

How really does supply chain management work?

As per the CIO, there are five parts of the conventional production network and the executive’s frameworks:

Planning:

Plan and deal with all assets expected to satisfy client needs for an organization’s item or administration. At the point when the production network is laid out, decide on measurements to quantify whether the inventory network is proficient, viable, conveys worth to clients, and meets organization objectives.

Manufacturing:

Sort out the exercises expected to acknowledge unrefined substances, fabricate the item, test for quality, bundle for transportation, and timetable for conveyance.

Returning:

Make an organization or cycle to reclaim blemished, the overabundance of undesirable items.

Conveyance and Logistics:

Coordinate client orders, plan movements, dispatch loads, receipt clients, and get portions.

Why supply chain management is important?

A positive or adverse consequence on the store network reverberates all through the business. There are two center regions to the effect: client satisfaction and ROI.

In January 2018, Tobin Moore from Optoro brought up this striking measurement at Retail’s Big Show: If a client is content with the manner in which their return cycle was taken care of, they’re 71% bound to turn into a recurrent client.

A smooth return process implies a powerful inventory network, one that is very much associated and includes correspondence along the chain. At the point when the store network meets or surpasses the assumptions of the client, this is a direct result of efficiencies. The whole business benefits through higher-request rates, positive feeling in the client’s brain, and lower cost-to-serve for the business.

Better execution is estimated as far as the proficiency of all cycles and individuals to move labor and products to showcase along the inventory network.

Expanded store network proficiency can mean tension in the group and their capacities, as expenses and spending plans are held level or decreased when they’re supposed to move something very similar or a more prominent volume of items at the equivalent or a better level.

Upgrades to benefits for the business are estimated by means of measurements like working capital turnover or money change execution; as business wellbeing improves, beneficial money the board and income transformation are the outcomes. Evening out the expense hump frequently turns into a test except if two variables are thought of: new capacities (interaction and information) that drive quicker, better choices; and utilizing a device that scales well for the worth it conveys for the business.

Conclusion

To lead the way into an extraordinary future, they need to consolidate specialized and business information with joint effort and relational abilities. The capacity to impact division pioneers that collaborate with the production network is critical, as well as the ability to interface shrewdly with pioneers across the association is fundamental since store network drives frequently reach across specialty units.

Furthermore, solid business discernment is an unquestionable requirement — you’ll be more successful working with your partners in money, deals, and showcasing on the off chance that you can talk their dialect. The successful inventory network head of tomorrow is well informed and open to working close by the universe of “machines.”