Small changes in requirements often have a big impact on the performance and cost of a system. For optimum performance of an optical system, there are several critical things you have to consider when selecting a thin-film coating.

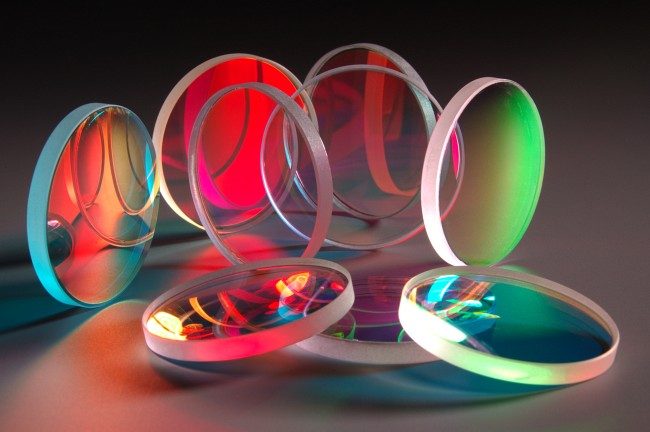

There are different types of thin-film coatings on the market. Among the popular options available are various electroplated, highly reflective, anti-reflection, and filter coatings.

7 Steps To Choosing The Best Optical Coating

Below is an overview of the important things to keep in mind when selecting an optical thin-film coating.

i) Your Application

Before starting to search for a thin-film coating, you have to know what you are trying to accomplish. This information is critical to determining whether the coating you select will meet the specifications and performance requirements of the optical system. The coating should also fit your budget.

Ideally, you should choose a thin-film coating that is most economical for your application.

ii) Type Of Coating

Consider the type of coating required. You should understand coating technology and know which one will be suitable for the application you have in mind. Depending on your project, you may also have to go for a standard or custom coating design.

iii) Wavelengths Involved

The best thin-film coatings for a specific application are typically determined by the transmission or reflection requirements at a certain wavelength of light. There are three different classes of light: infrared (IR), visible (VIS), and ultraviolet (UV).

- Infrared (IR). This light operates in the spectral wavelength range of 700 nm to upwards of 2500 nm. The light can be categorized into near, middle, and far-infrared radiation.IR is widely used in the military industry for thermal imaging applications, such as night vision and surveillance tracking. The light is also applied in spectroscopy and machine vision.

- Visible (VIS). Visible light spectrum ranges from 400 nm to 700 nm. This light is visible to the human eye and is used in many optical systems, including architectural lighting, movie projectors, searchlights, cameras, binoculars, and more.

- Ultraviolet (UV). UV light spans approximately 200 nm to 400 nm. The light is generally used for printing ink, adhesives, and curing paints. Other applications of UV light include in the manufacturer of circuit boards and in various therapeutic procedures.

Determining the wavelength region, which is usually derived from the application, will help you to decide whether to use a single or multilayer coating. A single layer coating has a limited range of wavelengths while a multilayer coating can perform over a greater spectrum.

iv) Reflection And Transmission Characteristics

Optical coatings are designed based on interference effects. Therefore, the transmission and reflection of light when it interacts with coating layers and the substrate will determine the performance of the coating. You can use optical thin-film coatings to enhance the transmission and reflection characteristics.

While multilayer coatings can achieve nearly 10X performance of single layer coatings, they are more complex and, therefore, generally expensive to manufacturer. Ultimately, the coating you should go for will depend on the performance requirements of your optical system.

v) Size Of The Part

Check the size of the parts of your system. This is important so that the thin-film coating manufacturer can design and use the most efficient production method. Generally, coatings that require tighter tolerance are costlier to the manufacturer because of the additional complex steps that have to be taken to achieve the required characteristics.

vi) Environmental Conditions

While thin-film coatings are durable, their performance over time can degrade, especially when they are exposed to extreme temperatures and humidity over a long period. High temperatures can alter the thickness and reflective index of the coating.

Consider the operating temperature of your system to determine whether the coating will be able to withstand it and still perform as expected.

vii) Quantity

The cost of thin-film coatings can be determined by the size of the coating run and part size. Many coating manufacturers do not offer technical assistance to help in coating design, Moreover, others just focus on a particular coating. Therefore, specific coating designs will be suitable for specific vendors.

Optical coatings are designed for particular optical systems to perform for specific requirements and under specific conditions. When looking for a coating, it is critical to choose a company like Evaporated Coatings, Inc. whose optical engineers can understand the exact requirements of your optical system and will be able to differentiate the capabilities and costs of various coating processes. The engineers should be able to advise you on the thin-film coating options that will be suitable for your system based on your performance requirements and budget.