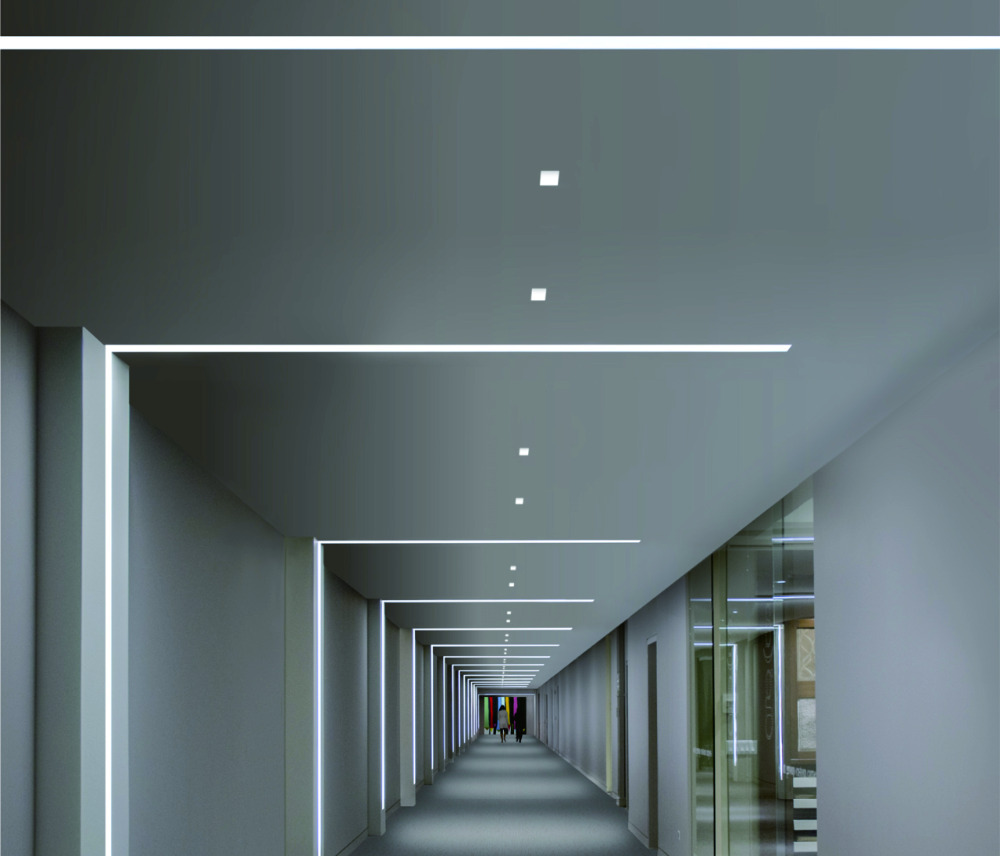

LED strip lights are an ideal and the most efficient lighting solution in the modern era. LED aluminum profile can be used in an efficient manner in order to produce customize low voltage lightning and it comprises of LED strip lights as well.

There are many benefits of using these aluminum profiles for LED strip lights such as they are eco-friendly budget-friendly durable study reliable contemporary and bright lighting fixtures.

These are all those features that everyone is looking for installing in their offices, homes, indoors, and outdoor areas. The best part about using these aluminum extrusions is that they can be used both commercially and residentially.

Overall it is a linear lighting solution with a multi-purpose usage. These lighting strips come in single and color-changing lights as well. These lights can be easily mounted in a big arrangement of aluminum tracks.

In this article, we are going to tell you how you can use aluminum profiles for the LED lights.

So keep on reading to find out more information below about aluminum profiles!

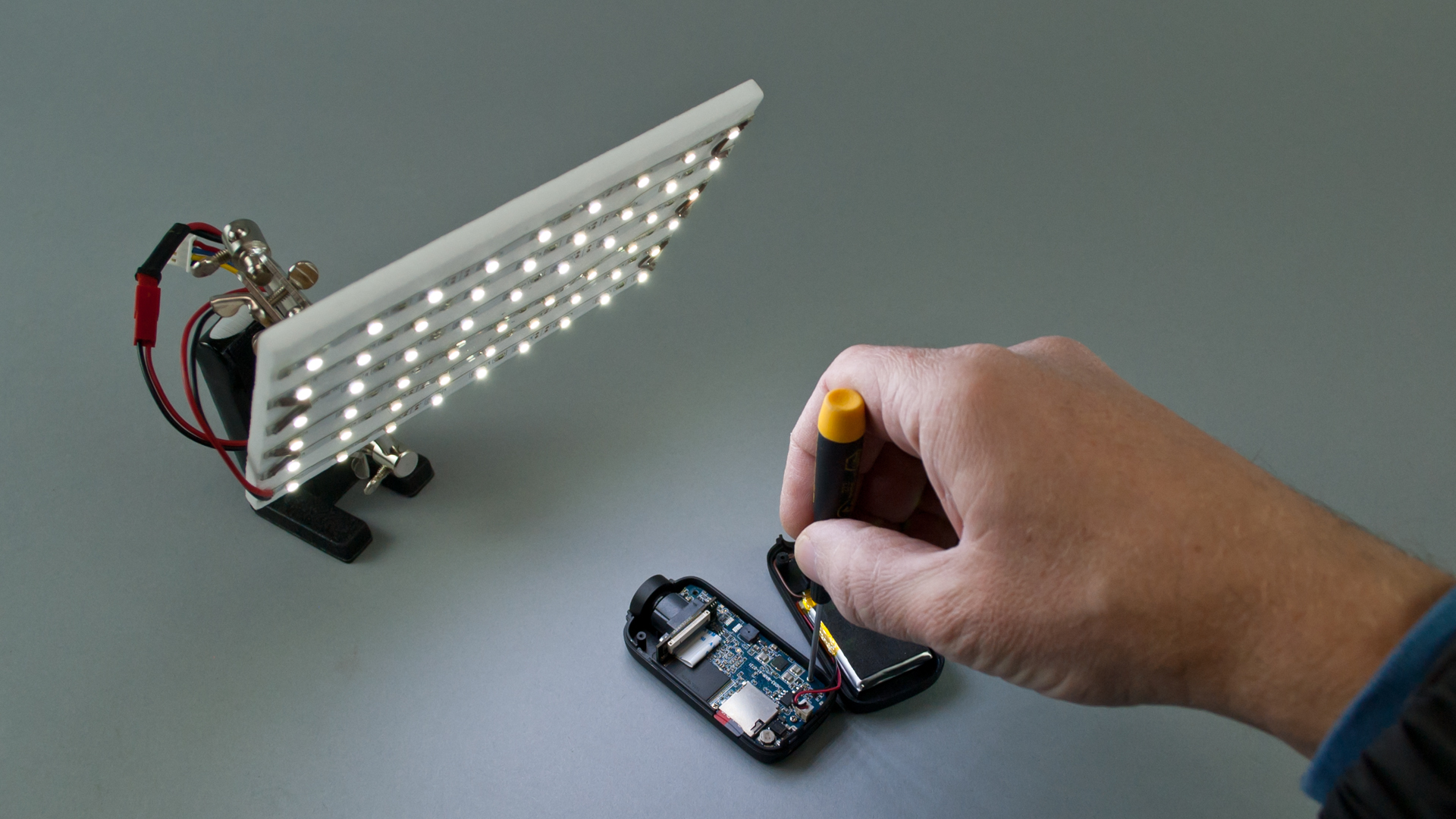

1. Soldering:

The first thing that you need to do is to prepare the wires for the soldering process full stop you can easily do this by stripping the wire by 1 by 8 inch off size.

Another important thing that you need to remember while doing this is to pass your wire through the last cap with hole full stop you must do this before the soldering process.

Another thing that you need to keep in mind is to use a larger, thicker, and good quality of wire for this purpose.

2. Solder The Wire:

The second step that you need to do is to finally solder the wire with the copper pads and make sure that there are no solder points that are touching each other full stop it is important to note that testing your connection before you install it is very important for the durability and safety.

3. Heat Shrink:

The next step is to analyze if any copper pads are exposed full stop if you see any exposed copper prayers and what you need to do is to use a heat shrink to cover up the exposed copper pad areas on the downside of the LED strip lights when you are working on your solder connection.

You need to make sure that no copper wire is exposed because exposed copper wire will cause an electrical shortage in the aluminum pathways and tracks.

4. Installation:

You can also use and caps to give a refined finish to the final outcome. But it is important to note that some and caps need a little bit of space for the installation process to take place appropriately. Then you need to measure and cut the strip according to the desired size.

5. Fixing The Tape:

The direction that you need to do is to clean the tape and then stick to the strip light.

Now you can use the plastic covers and press them into place.

6. Done:

Now you have done everything and you are good to go and enjoy your new installation that is successfully done!