Wire mesh is a remarkably versatile material used in a variety of industries, from construction and engineering to agriculture and design. This article delves into the world of wire mesh products, exploring their types, manufacturing processes, applications, and the trends influencing their usage.

Understanding Wire Mesh

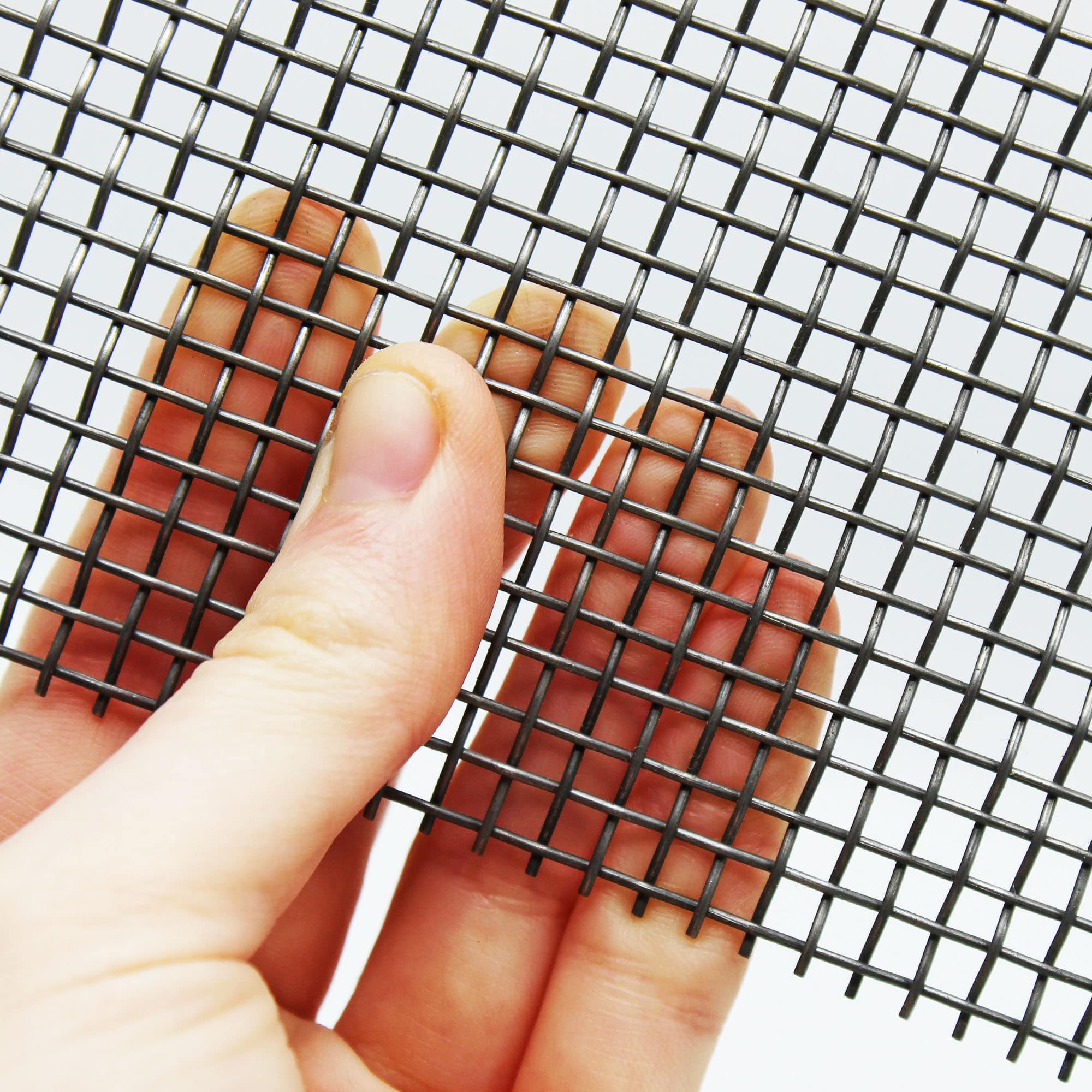

Wire mesh consists of intersecting wires that are woven or welded at the junctions to form a uniform and consistent grid-like pattern. The configuration can vary widely in terms of mesh size, wire gauge, and material, depending on the specific application. The primary materials used to manufacture wire mesh include stainless steel, low-carbon steel, copper, and aluminum, each selected for its particular properties, such as corrosion resistance, strength, and flexibility.

Types of Wire Mesh

Wire mesh products can be broadly categorized into woven and welded varieties:

- Woven Wire Mesh: This type is made by weaving metal wires on a loom, much like cloth. The process allows for a variety of patterns, with plain weave being the most common. Other patterns include twill weave and Dutch weave, which provide different levels of filtration and strength. Woven mesh is preferred when flexibility and precision are critical.

- Welded Wire Mesh: In this variety, wires are laid out in a grid and welded at the intersections. Welded mesh is known for its strength and rigidity, making it ideal for use in industrial applications where structural support is needed. It is less flexible than woven wire mesh but provides greater strength and consistency.

Manufacturing Process

The manufacturing of wire mesh involves several key steps, regardless of the type:

- Wire Drawing: This is the initial step where metal rods are drawn through progressively smaller dies to achieve the desired wire diameter.

- Weaving or Welding: Depending on the type of mesh required, wires are either woven on industrial looms or laid out and welded at the intersections.

- Finishing Processes: After weaving or welding, the mesh may undergo various finishing processes such as galvanizing, coating, or heat-treating to enhance its durability and performance characteristics.

Applications of Wire Mesh

The applications of wire mesh are diverse and extensive, reflecting its adaptability and effectiveness in various settings:

- Industrial Filtration: Wire mesh is widely used in industrial filtration, capturing particles and debris in systems ranging from automotive to food and beverage production.

- Construction: In the construction industry, welded wire mesh is used as reinforcement in concrete applications, significantly increasing the tensile strength of the structures.

- Agriculture: Wire mesh serves various functions in agriculture, including fencing, animal enclosures, and support structures for plants.

- Home and Garden: Decorative wire mesh is used in home and garden applications for items like cabinetry panel inserts, garden fencing, and home decor.

- Security: Wire mesh is also employed in security applications, forming barriers that are difficult to breach in secure facilities or as window screens in residential and commercial buildings.

- Architecture and Design: Architectural wire mesh is used for both functional and aesthetic purposes in buildings, such as facades, sunscreens, and interior partitions.

Market Trends and Innovations

The wire mesh industry is subject to several trends and innovations that reflect changing needs and technologies:

- Sustainability: There is an increasing demand for environmentally friendly materials and production processes. Wire mesh products made from recycled materials or those that offer energy efficiency benefits are becoming more popular.

- Customization: As applications become more specialized, the need for customized mesh sizes, shapes, and materials increases. Manufacturers are responding with more flexible production capabilities to cater to this demand.

- Integration with Technology: Advances in manufacturing technology, such as 3D printing and automated weaving, are expanding the possibilities for wire mesh products, allowing for more complex shapes and designs at lower costs.

Conclusion

Wire mesh is a fundamental material that plays a crucial role across various sectors due to its durability, versatility, and cost-effectiveness. As technology advances and new challenges arise, the wire mesh industry continues to evolve, developing new products and applications to meet an ever-expanding range of needs. Whether reinforcing a high-rise building, filtering impurities in industrial processes, or adding aesthetic value to a residential project, wire mesh products are integral to modern construction, manufacturing, agriculture, and design.