When you take your CPC4 Freightliner to a professional company, you don’t have to worry that this problem will happen to you. Many companies use a much more durable solder that can withstand extreme thermal cycles. In addition, they have professional repair processes that can fix these soldering issues without damaging the rest of the board.

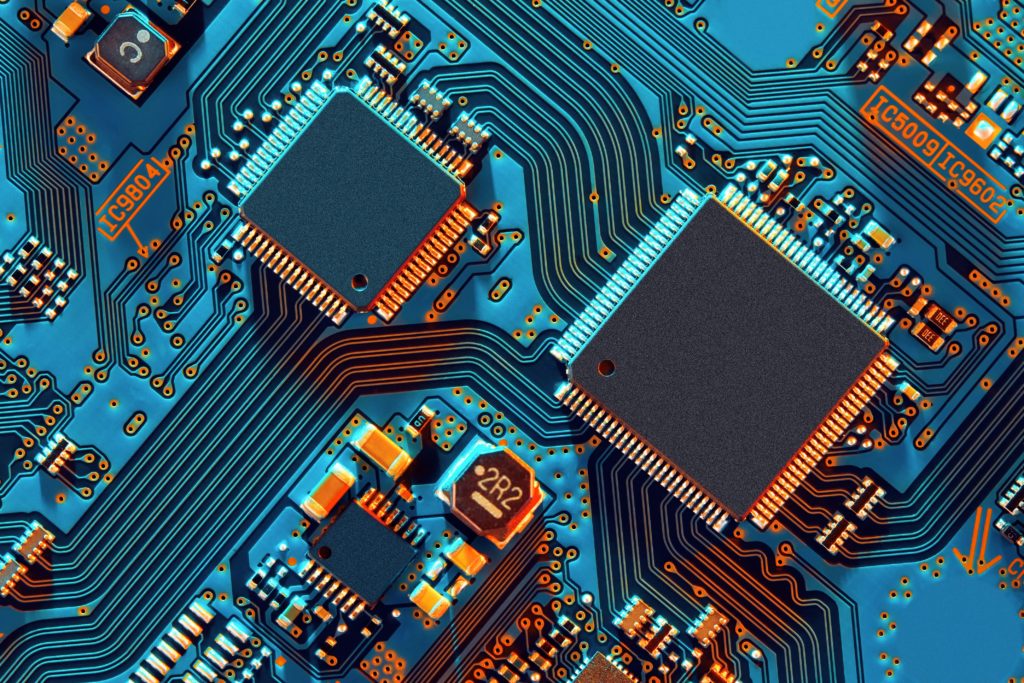

When the CPC4 module is sent for repair, the first thing that is done is to remove the conformal coating that is on the CPC board. Then the BGA chip is carefully removed. It is assessed to make sure it is not damaged and can be reused. The chip is cleaned so that all of the existing lead-free solders is completely removed. It is then carefully placed back onto the board and re-soldered using more durable solder. Fully automated workstations regulate the temperature at all times so that none of the surrounding components is damaged.

There is a multitude of DIY videos on the internet and blogs all describing in great detail that you can do this yourself at home, with a soldering stick and a hair dryer! If using such a method you are able to repair your CPC4 Freightliner module, it will be a quick fix at best, without addressing the actual issue and there is a high probability that you won’t be able to fix the module, but it will become damaged beyond repair.

Professional techniques and modern tools give reliable results. Professional companies perform meticulous bench testing and the CPC is thoroughly assessed for damage. x-ray machines are used to inspect and assess the solder joints located below the BGA and check for any defects. If you have a CPC4 issue, make sure you go to the professionals. They’ll have you back on the road in no time!