Quite often, total reliance on the functionalities of power tools is required to get a job done. And most power tools’ functionality is inseparable from the mechanism that keeps them in propulsion. Such a mechanism is made possible by carbon brushes in all power tools. Most power tools’ circuits are completed by conducting current between the static and rotating coil in a motor.

The carbon brushes are subjected to many conditions that favor wear and tear over some time due to their constant state of rotational motion. Although it is not a frequent occurrence, the possibility of the wear out of carbon brushes can necessitate the need for suitable replacements.

This article covers where to get your carbon brushes and seven signs that tell it’s time to replace them.

Where To Buy Carbon Brushes

It can sometimes be hard to find the right carbon brush for your power tool, particularly if it’s an older tool that is no longer manufactured. Choosing a carbon brush supplier in the UK like TDO Carbon can be a great option, as they stock a wide range of replacement carbon brushes to fit all sorts of tools, including legacy tools that are less popular. This can mean you get your favourite Bosch drill or Makita angle grinder back to work, without having to buy a new tool.

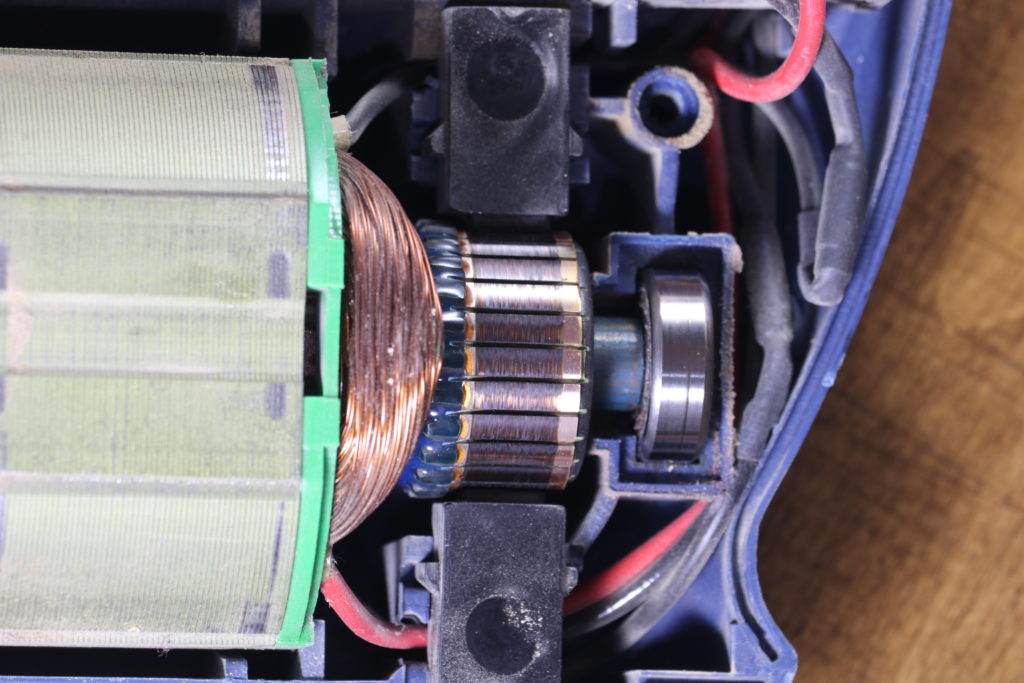

“Carbon Brushes for an Evolution Rage Saw”

To prevent irreversible damage to your power tool, early notice of the following signs can help you know when to get a replacement for your power tool’s carbon brush:

Inefficient Performance

This is one of the first signs the power tool operator feels. Although it is a general sign which can be associated with other malfunctioning parts, a worn carbon brush can reduce the overall performance of the power tool. There is an accumulation of dirt and debris in the tool with use. This accumulated dirt can find its way into the carbon brush channel and continuously erodes it.

The erosion of components of carbon brush shortens and prevents it from connecting with the armature commutator. A lack of contact between the carbon brush and armature commutator leads to interrupted flow of current and, subsequently, low or no power generation in the mechanical tool.

This inefficiency in performance can manifest physically as low power. The tool would underperform the work it’s specified for, and the regular shutdown of the tool when more power is required for work or an inability of the tool to power on when required. In such a situation, achieving the maximum revolution per minute (RPM) would be an almost impossible task, thereby causing a reduction in the tool’s mechanical advantage.

Sparks

The generation of sparks or smoke is a dangerous sign that requires a quick response. When observed, the tool should first be carefully switched off to prevent more complications or power outbreaks.

Ordinarily, any activity that causes blockage of the power tool’s air vent can lead to overheating and spark generation. This activity can be observed when carbon brushes start wearing out, and carbon specks from the wear are released into the carbon brush channel, later obstructing the air vent.

Also, due to improper fittings of the carbon brush in its holder, it can reverberate on the armature to generate unusual large sparks that are let out through the vents.

Burning Smell

Most power tools are composed of motors whose rotation subjects them to regular heat generation. It is not unusual for the heat to cause a burning smell. However, the brushes will arc due to heavy use, which creates a burning smell that can sometimes be accompanied by smoke or sparks.

When you sense a burning smell from any power tools, take your time to switch it off, physically inspect it, and consider replacing the carbon brush.

Unusual Banging Sound

In addition to the visible signs, unusual banging sounds emanating from the tool’s motor is an unmissable sign that the brush or any other components of the motor in power tools needs to be replaced.

An already deformed carbon brush will always bounce off the commutator as the armature reels around. As the carbon brush bounces off the commutator and hits other unassigned components of the motor, it makes a sound that is inconsistent with the normal operational sound given off by the tool. Therefore, any high-pitched noise that can be traced to a power tool’s motor is a sign that the carbon brush component or the entire motor needs to be replaced.

Physical Damage Or Discoloration

Physical inspection of the air vent of the power tool can give a hint on whether the carbon brush needs to be replaced or not. Visible crumbles of carbon brushes, discoloration sights occurring due to overheating, and heavy release of carbon specks from the vent are all evident indications that the carbon brush needs to be urgently replaced. These do not call for any assumptions, as delay in replacement can lead to mechanical damage to the tool’s components, especially the armature, which is expensive to replace.

Tool Starts Up After A Shake

A power tool should normally start without being smacked. If your power tool requires a gentle tap or heavy blow before it can be kicked into function, a carbon brush problem should be suspected.

When a carbon brush is stuck in its holder or channel, its expected contact with the armature is restricted, leading to an incomplete circuit. Since the circuit needs to be completed before the tool can start up, a gentle tap can thrust the brush back into contact with the armature and set the tool into motion.

If such occurs regularly, you may consider changing your tool’s carbon brush as it could have lost its fit.

Refusal To Power

This is probably the final sign as the carbon brush gets completely worn. As the brush channel shortens, the circuit required to power the tool becomes disrupted. This may cause the tool not to turn on. As it can be caused by other reasons asides from carbon brush, it is essential to check for other signs that can complement it. At this stage, extensive damage could have occurred to the power tool.

Conclusion

Most people consider using a power tool to get work done quite easily and quickly, and a sudden breakdown of such a tool can setback the flow of the person’s daily routine. You can completely avoid the power tool’s breakdown by looking for early signs of wear-outs or damage to the carbon brush. Likewise, the inconvenient expenses may come with the extensive damage incurred by a worn-out carbon brush.